Trong bài viết này Kỹ thuật sẽ hướng dẫn các bạn xử lý trường hợp xảy ra trên hosting khi import database xuất hiện thông báo lỗi: ` 1273 - Unknown collation: 'utf8mb4_unicode_520_ci'`Lỗi như trên là vì phiên bản MySQL hiện tại mà hosting đang chạy không hỗ trợ cho bảng mã utf8mb4_unicode_520_ci. Cũng có lúc bạn sẽ gặp lỗi: ` 1273 - Unknown collation: 'utf8mb4_unicode_ci' `với lý do tương tự.Bạn có thể tạo một file info.php để kiểm tra phiên bản MySQL đang chạy trên hosting của mình là gì để biết phiên bản đó có hỗ trợ bảng mã đó hay không. <?php phpinfo();?>

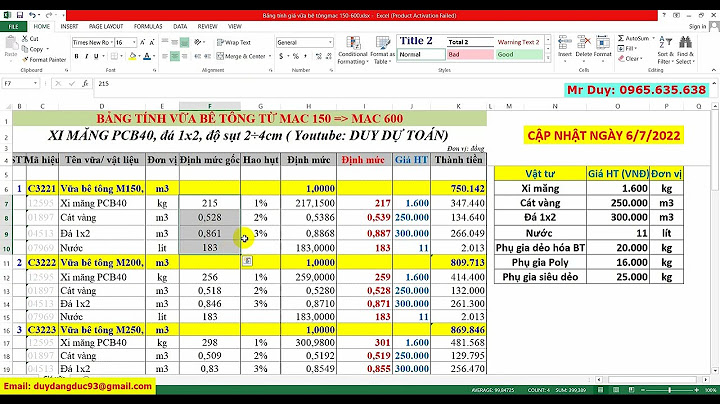

Theo như hình phiên bản MySQL mà hosting của Kỹ thuật đang dùng là 5.5.36. Với phiên bản MySQL này thì không hỗ trợ bảng mã utf8mb4_unicode_520_ci nhưng có hỗ trợ bảng mã utf8mb4_unicode_ci. Vậy làm cách nào để bạn import database sử dụng bảng mã utf8mb4_unicode_520_ci lên hosting đang chạy phiên bản MySQL 5.5.36? Ta sẽ có 2 cách: - Cách 1: Báo lại với nhà cung cấp dịch vụ của bạn yêu cầu họ nâng cấp phiên bản MySQL lên phiên bản 5.6 (phiên bản này có hỗ trợ bảng mã utf8mb4_unicode_520_ci)

- Cách 2: Chuyển đổi bảng mã utf8mb4_unicode_520_ci về các bảng mã mà phiên bản MySQL hiện tại bạn đang dùng có hỗ trợ.

Ở đây chúng ta sẽ không bàn đến cách 1, Kỹ thuật sẽ hướng dẫn các bạn làm cách 2. Với cách 2, đầu tiên bạn sẽ cần cài đặt Notepad++ để mở file database lên thì mình mới có thể chỉnh sửa được bảng mã. Tải về file cài đặt Notepad++ tại đây. Sau khi đã tải về và cài đặt Notepad++ trên máy tính cá nhân, bạn tiến hành mở file database lên bằng cách click chuột phải vào file và chọn Edit with Notepad++. Mở file lên xong, bạn sẽ tìm đến một bảng (table) gần nhất sẽ thấy bảng đó dùng bảng mã utf8mb4_unicode_520_ci. Giờ ta sẽ đổi toàn bộ bảng mã utf8mb4_unicode_520_ci thành utf8mb4_unicode_ci bằng cách dùng tính năng Replace của Notepad++. Bạn nhấn tổ hợp phim Ctrl+H hoặc là chọn Search > Replace như hình dưới. Có một toolbox sẽ xuất hiện giữa màn hình, bạn sẽ nhập utf8mb4_unicode_520_ci vào ô Find what, nhập utf8mb4_unicode_ci vào ô Replace with, sau đó nhấn Replace All. Tiến hành lưu lại file này và import database lại là thành công. Nếu các bạn gặp phải lỗi ` 1273 - Unknown collation: 'utf8mb4_unicode_ci' hoặc lỗi `You have an error in your SQL syntax; check the manual that corresponds to your MySQL server version for the right syntax to use near ' thì đó là do phiên bản MySQL hiện tại không hỗ trợ, bạn nên đổi về lại utf8_unicode_ci với cách như trên nhé.Máy CNC Fanuc là dòng máy của nhật bản được dùng khá phổ biến ở Việt Nam mà đa số là máy cũ đã qua sử dụng 1 thời gian lâu nên việc dựa vào các bảng mã lỗi để phục vụ công việc bảo trì, sửa chữa là rất cần thiết. Dưới đây là bản mã lỗi CNC Fanuc các đời từ thấp đến cao: Màn hình máy CNC báo lỗi 414 Servo AlarmBảng mã lỗi bộ điều khiển Fanuc series 0Alarm Code Description of Alarm/Error ??? BP/S alarm is produced with the same number as P/S alarm taking place in normal program editing. (070, 071, 072, 073, 074 etc) 140 An attempt was made to select or delete a program being selected in the foreground. Program P/S AlarmsAlarm Code Description of Alarm/Error 000 A parameter which requires the power off was input, turn off power. 001 TH alarm ( A character with incorrect parity was input. Correct the tape. 002 TV alarm ( The number if characters in a block is odd). This alarm will be generated only when the TV check is effective. Correct the tape. 003 Data exceeding the maximum allowable number of digits was input. (Refer to the item of max.programmable dimensions) 004 A numeral of the sign “-” was input without an address at the beginning of a block. 005 The address was not followed by the appropriate data but was not followed by another address or EOB code. 006 Sign “-” input error ( Sign “-” was input after an address with which it cannot be used. Or two or more “-” signs were input) 007 Decimal point “-” input error. 009 Unusable character was input insignificant area. 010 An unusable G code was commanded. 011 Feedrate was not commanded to a cutting feed or the feedrate was inadequate. 014 In variable lead threading the lead incremental and decremental outputted by address K exceed the maximum command value or a command such that the lead becomes a negative value is given. 015 The number of the commanded axes exceeded that of simultaneously controlled axes. 021 An axis not included in the selected plane was commanded in circular interpolation. 023 In circular interpolation by radius designation negative value was commanded for address R. 029 The offset value is too large. 030 The offset number specified by * code for tool length offset (or cutter compensation is too large.) 031 In setting an offset amount by G10, the offset number following address P was excessive or it was not specified. 032 In setting an offset amount by G10, the offset amount was excessive. 033 A point of intersection cannot be determined for cutter compensation C/ Tool nose radius compensation. 034 The start up or cancel was going to be performed in the G02 or G03 mode in cutter compensation C/tool nose radius compensation. 035 G39 is commanded in cutter compensation B cancel mode or on the plane other than offset plane/Ship cutting (G31 was specified in tool nose radius compensation mode. 036 Skip cutting (G31) was specified in cutter compensation mode. 037 G40 ( offset cancel) is commanded at the plane other than the offset plane in cutter compensation B. The plane selected by using G17, G18, G19 is changed in cutter compensation C mode. 038 Overcutting will occur in cutter compensation C because the arc start point or end point coincides with the arc centre/Overcutting will occur in tool nose radius compensation C because the arc start point or end point coincides with the arc centre/ 039 Chamfering or corner R was specified with a start up, a cancel, or switching between G41 and G42 in tool nose radius compensation. The program may cause overcutting to occur in chamfering or corner R. 040 Overcutting will occur in tool nose radius compensation in a canned cycle G90 or G94. 041 Overcutting will occur in cutter compensation C/ tool radius compensation. 044 One of G27 to G30 is commanded in canned cycle mode. 050 The chamfering or a corner R was specified in a block which includes a thread cutting command. 051 The block after a block containing a chamfering or a corner R specification was not a G01 command. 052 The move direction or the move amount in a block following chamfering or a corner R command was not adequate. 053 2 or more of I, K and R are directed in chamfering and corner radius R command or C or R does not come after a comma (,) in direct drawing dimension programming. 054 A block in which the chamfering or the corner R was specified includes a taper command. 055 The move distance in the block which includes the chamfering or the corner R specification is smaller than the chamfering amount 056 Both end point and angle are not designated in the next block command of the angle designation block (A_). I (K) is commanded to X axis ( Z axis) in chamfering command. 057 Block end point is not calculated correctly in direct dimension drawing programming. 058 Block end point is not found in direct dimension drawing programming. 059 The program with the selected number cannot be searched in external program number search. 060 Commanded sequence number was not found in the sequence number search. 061 Address P or Q is not specified in G70, G71, G72 or G73 command. 062 The depth of cut in G71 or G72 is zero or negative value.The repetitive count in G73 is zero or negative value. The negative value is specified to A1 or Ak in G74 or G75. A value other than zero is specified to Ad, though the relief direction in G74 or G75 is determined. Zero on a negative value is specified to the height of thread of depth of cut of 1st time in G76. The specified minimum depth of cut in G76 is greater than the height of thread. An unusable angle of tool tip is specified in G76. 063 The sequence number specified by address P in G70, G71, G72 or G73 command cannot be searched. 065 G00 or G01 is not commanded at the block with the sequence number which is specified in address P in G71, G72 or G73 command.Address Z (W) or X (U) was commanded in the block with a sequence number which is specified by address P in G71 or G72 respectively. 066 An allowable G code was commanded between two blocks specified by address P and Q in G71, G72, G73. 067 G70, G71, G72 or G73 command with address P and Q was specified in MDI mode. 069 The final move command in the blocks specified by P and Q of G70, G71, G72 and G73 ended with chamfering or corner R. 070 The memory area is insufficient. 071 The address to be searched was not found. Or the program with specified program number was not found in program number search. 072 The number of programs to be stored exceeded 63 or 125. 073 The commanded program number has already been used. 074 The program number is other than 1 to 9999. 076 Address P was not commanded in the block which includes an M98 or a G65 command. 077 The subprogram was called in three or five folds. 078 A program number or a sequence number which was specified by address P in the block which includes an M98, M99 or G66 was not found. 079 The contents of the program stored in the memory did not agree with that in tape in collection. 080 In the area specified by parameter E, the measuring position reach signal does not come on. 081 Automatic tool compensation was specified without a T code. 082 T code and automatic tool compensation were specified in the same block. 083 In automatic tool compensation an invalid axis was specified or the command is incremental. 085 When entering data in the memory by using ASR or Reader/puncher interface , an overrun, parity or framing error was generated. The number of bits or input data or setting of baud rate is incorrect. 086 When entering data in the memory by using Reader/puncher interface , the ready signal (DR) of reader/puncher was turned off/. 087 When entering data in the memory by using Reader/puncher interface , though the read terminate command is specified input is not interrupted after 10 characters read. 090 The reference point return cannot be performed normally because the reference point return start point is too close to the reference point or the speed is too slow. 092 The commanded axis by G27 did not return to the reference point. 094 P type cannot be specified when the program is restarted. 095 P type cannot be specified when the program is restarted. 096 P type cannot be specified when the program is restarted. 097 P type cannot be specified when the program is restarted 098 A command of the program restart was specified without the reference point return operation after power ON and emergency stop and G28 was found during search. 099 After completion of search in program restart, a move command is given with MDI. 100 Setting data PWE is set to 1. Turn it to 0 and reset the system. 101 The power was turned off while rewriting the contents of the memory in the part program storage and editing operation. When this alarm is generated set the data PWE to 1 and turn on the power while pushing DELETE to clear the memory. 111 The calculation result of macro instruction exceeds the allowable range. 112 Division by Zero was specified. ( including tan 90 degrees) 114 An undefined H code is designated in G65 block. 115 A value not defined as a variable number is designated. 116 The variable number designated with P is forbidden for assignment. 119 The argument of SQRT or BCD is negative. 122 The macro model call is specified in double. 125 In the block with G65, the unusable address was specified.. 128 The sequence number specified in the brand command was not 0 to 9999. Or, it cannot be searched. 130 In 3rd axis control, a 3rd axis control command was given by PMC during Cf control. On the contrary an attempt was made for spindle indexing. 135 Without any spindle orientation, an attempt was made for spindle indexing. 136 A move command of other axes was specified to the same block as spindle indexing addresses C, H. 137 A move command of other axes was specified to the same block as M code related to spindle indexing. Absolute Pulse Code (APC) AlarmsAlarm Code Type Description of Alarm/Error 3n0 nth-axis origin return Manual reference position is required for the nth axis. 3n1 APC alarm: nth axis communication nth axis communication error. Failure in data transmission. 3n2 APC alarm: nth axis over time nth axis APC overtime error. 3n3 APC alarm: nth axis framing nth axis APC overtime error. Failure in data transmission. 3n4 APC alarm: nth axis parity nth axis APC Paraity error. Failure in data transmission. 3n5 APC alarm: nth axis pulse error nth axis APC pulse error alarm. 3n6 APC alarm: ntha xis battery voltage 0 nth axis APC battery voltage has decreased to a low level so that data cannot be held. 3n7 APC alarm: nth axis battery low 1 nth axis axis APC battery voltage reached a level where the battery must be renewed 3n8 APC alarm: nth axis battery low 2 nth axis axis APC battery voltage reached a level where the battery must be renewed( including when power is OFF) 3n9 SPC ALARM: n AXIS PULSE CODER The n axis ( axis 1-8) pulse coder has a fault. Servo AlarmsAlarm Code Type Description of Alarm/Error

400 SERVO ALARM: 1, 2TH AXIS OVERLOAD 1-axis, 2-axis overload signal is on. 401 SERVO ALARM: 1, 2TH AXIS VRDY OFF 1-axis, 2-axis servo amplifier READY signal (DRDY) went off. 402 SERVO ALARM: 3, 4TH AXIS OVERLOAD 3 axis, 4 axis overload signal is on. 403 SERVO ALARM: 3, 4TH AXIS VRDY OFF 3-axis, 4 axis servo amplifier READY signal (DRDY) went off. 404 SERVO ALARM: n-TH AXIS VRDY ON Even though the n-th axis ( axis 1-8) READY signal ( DRDY) is still on. Or, when the power was turned on, DRDY went on even though MCON was off. 405 SERVO ALARM: ZERO POINT RETURN FAULT Position control system fault. 406 SERVO ALARM: 7, 8TH AXIS OVERLOAD7TH, 8TH AXIS VRDY OFF 7-axis, 8-axis overload signal is on. 4n0 SERVO ALARM: n-TH AXIS -EXCESS ERROR The position deviation value when the n-th axis stops is larger than the set value. 4n1 SERVO ALARM: n-AXIS-EXCESS ERROR The position deviation value when the n-th axis stops is larger than the set value. 4n3 SERVO ALARM: n-th AXIS -LSI OVERFLOW The contents of the error register for the n-th axis exceeded power. 4n4 SERVO ALARM: n-TH AXIS DETECTION RELATED ERROR N-th axis digital servo system fault. 4n5 SERVO AALRM: n-TH AXIS- EXCESS SHIFT A speed higher than 4000000 units/s was attempted to be set in the n-th axis. 4n6 SERVO ALARM: n-TH AXIS -DISCONNECTION Position detection system fault in the n-th axis pulse coder ( disconnecton alarm). 4n7 SERVO ALARM: n-TH AXIS-PARAMETER INCORRECT This alarm occurs when the n-th axis is in one of the conditions below: - The value set in Parameter no 8n20 (motor form) is out of the specified limit.

- A proper value ( 111 or -111) is not set in parameter no 8n22.( motor revolution direction).

- Illegal data ( a value below 0, etc) was set in parameter No 8n23 ( number of speed feedback pulses per motor revolution)

- Illegal data ( a value below 0, etc) was set in parameter No 8n24 ( number of speed feedback pulses per motor revolution)

- Parameters No. 8n84 and No. 8n85 (flexible field gear rate) have not been set.

- An axis selection parameter ( from No.269 to 274 is incorrect.

- An overflow occured during parameter computation.

490 SERVO ALARM: 5TH AXIS OVERLOAD 5-axis, 6-axis overload signal is on. 491 SERVO ALARM: 5, 6TH AXIS VRDY ON 5-axis, 6-axis servo amplifier READY signal (DRDY) went off. 494 SERVO ALARM: 5, 6TH AXIS VRDY ON The axis card ready signal ( MCON) for axes 5 and 6 is off, but the servo amplifier ready signal (DRDY) is not. Alternatively when the power is applied, the DRDY is on and the MCON is not. 495 SERVO ALARM: 5, 6TH AXIS ZERO POINT RETURN This is a position control circuit error.

Overtravel AlarmsAlarm Code Description of Alarm/Error 510 Overtravel to exceed the (+) stroke limit of the X-axis 511 Overtravel to exceed the (-) stroke limit of the X-axis 512 2nd stroke limit at + side of X axis was exceeded 513 2nd stroke limit at + side of X axis was exceeded 520 Overtravel to exceed the (+) stroke limit of Y axis (M) or Z-axis (T) 521 Overtravel to exceed the (-) stroke limit of Y axis (M) or Z-axis (T) 522 2nd stroke limit at + side of Z axis was exceeded 523 2nd stroke limit at – side of X axis was exceeded 530 Overtravel to exceed the (+) stroke limit of Z-axis 531 Overtravel to exceed the (-) stroke limit of Z-axis 540 Overtravel to exceed the (+) stroke limit of the 4th axis 541 Overtravel to exceed the (-) stroke limit of the 4th axis Alarm in Fanuc PMC Model L/MAlarm Code Description of Alarm/Error 600 Interruption by illegal command is occurred 601 PMC RAM parity error is occured 602 PMC serial transmission error is occurred 603 PMC watch dog error is occurred 604 PMC ROM parity error is occurred 605 LADDER contents which can be stored in PMC is exceeded Overheat AlarmsAlarm Code Description of Alarm/Error 700 Master PCB is overheated 702 X, Y, (M), or Z axis servo motor is overheated 703 4th axis servo motor is overheated System AlarmsAlarm Code Type Description of Alarm/Error 910 MAIN RAM PARITY This RAM parity error is related to low-order-by-test. 911 MAIN RAM PARITY This RAM parity error is related to the low-order bytes. 912 SHARED RAM PARITY This RAM parity error is related to the low-order bytes of RAM shared with the digital servo circuit. 913 SHARED RAM PARITY This parity error is related to high-order bytes of RAM shared with the digital servo cicuit. 914 SERVO RAM PARITY This is a local RAM parity error in the digital servo circuit. 915 LADDER EDITING CASSETTE RAM PARITY This RAM parity error is related to low order bytes of the ladder editing cassette. 916 LADDER EDITING CASSETTE RAM PARITY This RAM parity error is related to the high order bytes of the ladder editing cassette. 920 WATCHDOG ALARM This is a watchdog timer aalrm or a servo system alarm for axis 1 to 4. 921 SUB CPU WATCH DOG ALARM This is a watchdog timer alarm related to the sub-CPU board or a servo system alarm for axis 5 or 6. 922 7/8 AXIS SERVO SYSYTEM ALARM This is a servo system alarm related to axis 7 or 8. 930 CPU ERROR Replace the master PC board. 940 PC BOARD INSTALLATION ERROR PC board installation is incorrect. Check the specification of the PC board. 941 MEMORY PC BOARD CONNECTION ERROR The memory PC board is not connected securely. 945 SERIAL SPINDLE COMMUNICATION ERROR The hardware configuration is incorrect for the serial spindle, or a communication alarm occured. 946 SECOND SERIAL SPINDLE COMMUNICATION ERROR Communication is impossible with the second serial spindle. 950 FUSE BLOWN ALARM A fuse has blown 960 SUB CPU ERROR This is a sub-CPU error. 998 ROM PARITY This is a ROM parity error. Bảng mã lỗi bộ điều khiển Fanuc 0i hay OiAlarm Code Description of Alarm/Error 000 Re-apply the power after the parameter has been input 001 TH Alarm (A character with incorrect parity was input) Correct the tape 002 TV Alarm (The number of characters in a block is odd). This alarm is generated only when the TV check is effective 003 Data exceeding the maximum allowable number of digits was input 004 A numeral or the sign (-) was input without an address at the beginning of the block 005 The address was not followed by the appropriate data but was followed by another address of EOB code 006 Sign “-” input error (sign “-” was input after a address with which it can’t be used. Or two “-” signs were used). 007 Decimal Point “.” Input error (A decimal point was input after a address with which it can’t be used. Or input of two decimals). 008 The switch position of the tape reader was not AUTO (without reel) or REEL ON/REEL OFF (with reels). 009 Unusable character was input. (E). 010 A unusable G code was commanded. (The alarm is generated also when a G code with which the control is not equipped as an option is commanded). 011 Feed rate was not commanded at cutting feed or the feed rate was inadequate 015 The number of the commanded axes exceeded that of the allowable simultaneously controlled axis 017 The move commanded of the additional axis was commanded without equipping with an optional additional axis. 018 An additional axis was commanded with the other axis simultaneously. 021 The axis not included in the selected plane (by using G17, G18, G19) was commanded in circular interpolation. 022 In circular interpolation, radius designation was performed in the NC which is not equipped with the radius designation option. 023 In circular interpolation by radius designation, Zero was commanded for address R. 030 The tool offset number is too large for the D or H function. 031 In setting of offset amount by G10, The offset number following address P was excessive or it was not specified. 032 In setting of offset amount by G10, the offset amount was excessive. 035 Skip Cutting (G31) was commanded in cutter compensation mode. 036 G45-G48 (Tool Offset) was commanded in cutter compensation mode. 037 The selected (by using G17, G18 or G19) changed in cutter compensation mode. 038 Over cutting will occur in cutter compensation because the arc start point or end point coincides with arc center 041 Overcutting will occur in cutter compensation. 044 One of G27-G30 was commanded in canned cycle mode. In canned cycle mode, an ATC cycle (M06) is commanded. 045 An ATC cycle (M06) was commanded for the NC which is not equipped with optional reference point return feature. 046 Other than P2, P3 and P4 was specified in the 2nd, 3rd and 4th reference point return commands. 047 G27 to G30 was commanded for and axis which does not have a reference point. 058 In 4-digit S code binary 12-bit/analogue output A, A command was specified exceeding the maximum or minimum number of spindle revolutions. 059 No program for selected work number is found (external work number select A function). 060 Commanded sequence number was not found in the sequence number search, 065 Scaling Magnification was specified as other than 1-99999. 066 Scaling was applied and as a result, movement value, coordinate value, circular arc radius, etc. exceed maximum programmable dimension. 067 G51 (scaling ON) was specified in cutter compensation mode. 070 The fanuc memory area is insufficient. 071 The address to be searched was not found. 072 The number of programs to be stored exceeds 95 or 191. (191 is a option) 073 The program number has already been used. 074 The program number is other then 1-9999 075 The program number or sequence number was not found at the start block of the program 076 The address P was commanded in the block with includes a M98 command. 077 The subprogram was called in triple 078 The sequence number which was specified by address P in the block which includes a M98 or M99 was not found 079 Memorized program and tape contents do not coincide 085 When storing data in memory by using ASR or RS232C interface, an over-run or framing error was generated 086 The signal level of RS232C interface was incorrect 087 When storing data in the memory by using the fanuc RS232 interface, the time required to store the data is insufficient. 090 The reference point return cannot be performed normally because the reference point return start point is to close to the reference point or one revolution signal is not input owing to a fault in the pulse coder. 091 Reference point return cannot be executed normally, because of the feed rate is too low to synchronize the one revolution signal of the pulse coder with the reference counter, 092 The axis designated by G27 did not return to reference point. 094 No P type can be specified for program restart (because after program interruption, coordinate system setting or ORIGIN, etc. was executed) 095 No P type can be specified for program restart (because after program interruption, external work zero point offset value changed) 096 No P type can be specified for program restart (because after program interruption, work zero point offset value changed). 097 No P type can be specified for program restart (because after program interruption, no automatic operation has been executed). 100 The switch to set parameters is on. Push the reset button after turning off the switch. 101 The power was turned off while rewriting the contents of memory in the part program storage & editing operation. To clear the memory when this alarm is generated turn on the power and push the DELETE and RESET buttons. 110 Absolute value of data of fixed point representation exceeds the upper bound (99999999). 111 Exponent of data of floating point representation exceeds the upper bound. 112 Divisor is 0 113 A function that cannot be used by user macro A is used 114 Format error except for 115 Value not defined as variable number is assigned 116 Left side of substituted sentence is a variable of prohibited substitution 118 Nesting of brackets exceeds the upper limit (5). 119 Argument of SQRT is negative , Or argument of BCD is negative 122 Nesting of macro exceeds the upper limit (4) 123 Macro control command is uded in tape mode 124 DO END is not 1:1 corresponding 125 Format error of (formula) 126 Not 1 £ n £ 3 in DO n 127 NC command and macro command are mixed 128 Not 0 £n £9999 in GO TO n 129 Unallowable address is used in . 130 In external data input, greater-address data contains an error 131 In external alarm message, five or more alarms have occurred 132 In external alarm message, clear, no corresponding alarm number exists 133 In external alarm message and in external operator message, smaller- address data contains an error 170 Programs of numbers 8000 – 8999 and 9000 – 9899 are being edited, But this alarm occurs only when parameter setting inhibits these programs to be edited. Error on Stroke Limit Switch 210 The movable part of machine touched the X Axis plus stroke limit switch 211 The movable part of machine touched the X Axis minus stroke limit switch 212 While the X Axis was moving in the plus direction, It entered into the forbidden area of the stored stroke limit 1 213 While the X Axis was moving in the minus direction, It entered into the forbidden area of the stored stroke limit 1 214 While the X Axis was moving in the plus direction, It entered into the forbidden area of the stored stroke limit 2 215 While the X Axis was moving in the minus direction, It entered into the forbidden area of the stored stroke limit 2 220 The movable part of the machine touched the Y axis plus stroke limit switch 221 The movable part of the machine touched the Y axis minus stroke limit switch. 222 While the Y axis was moving in the plus direction, it entered into the forbidden area of the stored stroke limit 1 223 While the Y axis was moving in the minus direction, it entered into the forbidden area of the stored stroke limit 1 224 While the Y axis was moving in the plus direction, it entered into the forbidden area of the stored stroke limit 2 225 While the Y axis was moving in the minus direction, it entered into the forbidden area of the stored stroke limit 2 230 The movable part of the machine touched the Z axis plus stroke limit switch 231 The movable part of the machine touched the Z axis minus stroke limit switch 232 While the Z axis was moving in the plus direction, it entered into the forbidden area of the stored stroke limit 1 233 While the Z axis was moving in the minus direction, it entered into the forbidden area of the stored stroke limit 1 234 While the Z axis was moving in the plus direction, it entered into the forbidden area of the stored stroke limit 2 235 While the Z axis was moving in the minus direction, it entered into the forbidden area of the stored stroke limit 2 240 The movable part of the machine touched the 4th axis plus stroke limit switch 241 The movable part of the machine touched the 4th axis minus stroke limit switch. Error on servo system 400 The control received the X, Y or Z axis overload signal 401 The READY signal (VRDY) of the X, Y or Z axis velocity control has turned off 402 The control received the 4TH axis overload signal 403 The READY signal (VARY) of the 4TH axis velocity control has turned off 404 The READY signal (VARY) of the X, Y or Z axis velocity control does not turn off even though the READY signal (PRDY) of the position control has turned offThe READY signal (VARY) of velocity control already on even though the READY signal (PRDY) of the position control is off yet at power on condition 405 In reference point return, reference point return is not performed in correctly by abnormality of NC control section or servo system. Perform manual reference point return again 410 The content of error register of the X axis is larger than the value allowed while the machine is stopped 411 The content of error register of the Y axis is larger than the value allowed while the machine is moving 412 Drift in X axis is excessive. (Exceeds 500VELO) 413 The content of the error register of the X axis exceeded =32767. Or the velocity command value of the DA converter is out of the range of +8191~ – 8192. Incorrect settings will cause this alarm 414 The resolver/inductosyn position detecting system of X axis is trouble 415 A feed rate exceeding 511875 detection units/sec was commanded in the X axis. An incorrect setting of CMR causes this error 416 X axis pulse coder position feedback is abnormal. (Disconnection alarm) 420 The content of the error register of the Y axis is larger than the value allowed while the machine is stopped 421 The content of the error register of the Y axis is larger than the value allowed while the machine is moving 422 Drift in Y axis is excessive. (Exceeds 500VELO) 423 The content of the error register of the Y axis exceeded =32767. Or the velocity command value of the DA converter is out of the range of +8191~ – 8192. Incorrect settings will cause this alarm 424 The DSCG position detecting system of the Y axis is trouble 425 A feed rate exceeding 511875 detection units/sec was commanded in the Y axis. An incorrect setting of CMR causes this error 426 Y axis Fanuc pulse coder position feedback is abnormal. (Disconnection alarm) 430 The content of the error register of the Z axis is larger than the value allowed while the machine is stopped 431 The content of the error register of the Z axis is larger than the value allowed while the machine is moving 432 Drift in Z axis is excessive. (Exceeds 500VELO) 433 The content of the error register of the Z axis exceeded =32767. Or the velocity command value of the DA converter is out of the range of +8191~ – 8192. Incorrect settings will cause this alarm 434 The resolver/inductosyn position detecting system of Z axis is trouble 435 A feed rate exceeding 511875 detection units/sec was commanded in the Z axis. An incorrect setting of CMR causes this error 436 Z axis pulse coder position feedback is abnormal. (Disconnection alarm) 440 The content of the error register of the 4TH axis is larger than the value allowed while the machine is stopped 441 The content of the error register of the 4TH axis is larger than the value allowed while the machine is moving 442 Drift in 4TH axis is excessive. (Exceeds 500VELO) 443 The content of the error register of the 4THaxis exceeded =32767. Or the velocity command value of the DA converter is out of the range of +8191~ – 8192. Incorrect settings will cause this alarm 444 The resolver/inductosyn position detecting system of the 4TH axis is trouble 600 Data transferring error took place in the connection unit or in PC-model C 601 Slave relay was turned off. (Connections among unit, MDI/DPL (MDI/CRT) and master PCB are trouble. Also in another case change connection unit) 602 PC program has not yet been loaded 603 The correspondence between NC and PC is incorrect or interrupted. Change power sequence control PCB or master PCB 604 No hold is effective to PC-model B side MPU 605 A system error has occurred in PC-model B side MPU 606 RAM/ROM parity has occurred in PC-model B side MPU 607 Data transferring error took place in Fanuc MDI & CRT. Overheat alarm 700 Overheat of the master PCB 701 Overheat of the PCB for 4TH axis 702 Overheat of DC motor for X, Y, Z axis 703 Overheat of DC motor for 4TH axis. Errors on memory 900 Fault in bubble device. (Fault of input signal for bubble device) 901 Fault in bubble device. 902 Fault in bubble device. (Page size error, undefined command) 903 Fault in bubble device. (Transfer missing, page size over) 904 Fault in Fanuc bubble device. (Parity error) 905 Fault in bubble device. (No marker) 906 Fault in bubble device. (Many defect loops) 910 RAM parity error (low byte) 911 RAM parity error (high byte) 920 System error (watch dog timer alarm) 930 CPU error (0, 3, 4 type interrupt generation) 997 ROM parity error (PC ROM) 998 ROM parity error (Basic ROM) 999 ROM pair error (No correspondence between high and low) Background Edit AlarmAlarm Code Type Description of Alarm/Error ???? BP/S alarm BP/S alarm occurs in the same number as the P/S alarm that occurs in ordinary program edit. 140 BP/S alarm It was attempted to select or delete in the program being selected in the foreground. (Note) Note: Alarm in background edit is displayed in the key input line of the background edit screen instead of the ordinary alarm screen and is resettable by any of the MDI key operation. |